6CRT-55 green tea leaves rolling machine barrel diameter is 550mm, height 400mm, productivity is 75kg/h

TQJ-20 Fresh tea leaf wither rack has bamboo and stainless steel plate, can use for all kinds tea.

DL-6CSTL-Q80 gas heating continuous tea leaf steaming machine can use for many kinds of tea, such as green tea, oolong tea and others.

DL-6CHZ-Q14 tea drying machine can use liquid gas, natural gas and electric, can dry all most kinds tea, such as green tea, black tea, oolong tea and so on.

DL-6CFJ-80 black tea fermentation machine mainly used for processing black tea, let black tea ferment better.

DL-4C-T50A5 handheld one-man tea leaf plucking machine cutting width is 450mm, 500mm, 600mm, use HUASHENG 1E34F gasoline engine.

DL-4CD-35 electric battery operated tea leaf plucker harvesting machine cutting width is 350mm, using backpack lithium battery or lead acid battery.

DL-6CY3-15 tea cake and tea brick molding machine use hydraulic, can press puer tea cake and other tea cake and tea brick.

DL-6CST-50 gas heating green/oolong tea panning machine can use 220V and 380V, inner diameter 50cm, highest temperature can be 350℃, it can process 25kg tea per hour.

DL-6CRH-120B tea leaf bamboo soft basket with cloth covering mainly used for temporary storage of tea, easy to transfer tea between each processing process.

DL-6CFX-435QB used for sorting different kind tea, screen out strip tea, broken tea and tea powder of different specifications

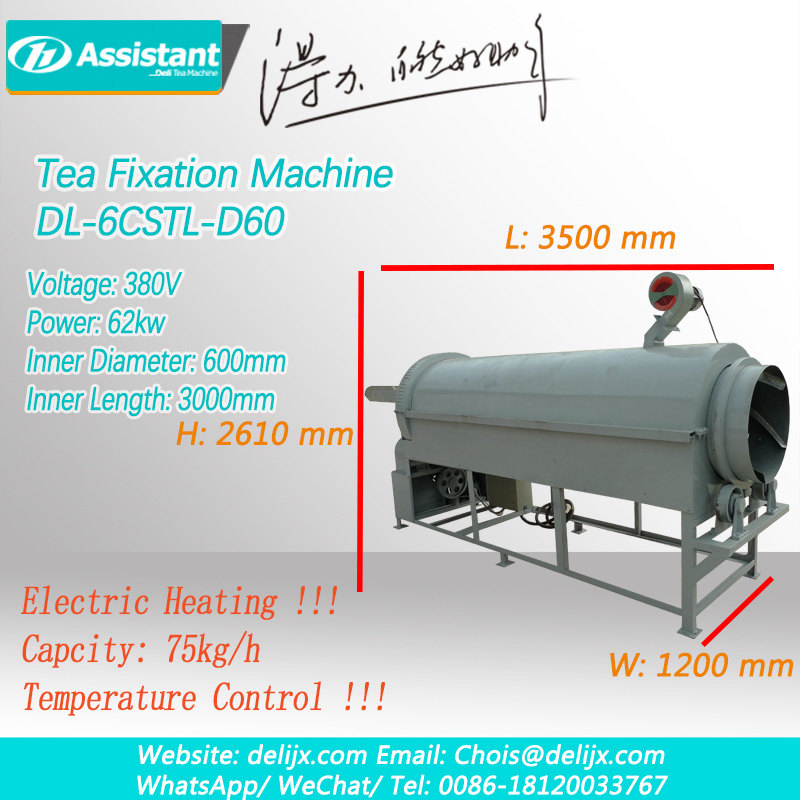

Item NO.:

DL-6CSTL-D60Brand:

DELI ASSISTANTDimension:

900×3500×1516 mmVoltage:

380/50 V/HzBarrel diameter:

600 mmBarrel length:

3000 mmHeating power:

62 KWBarrel speed:

5-37 rpmHeating type:

Electric heating wireEfficiency:

75 kg/h

| Description: |

| Application: |

| Advantage: |

| Parameter: |

| Model | DL-6CST-L60D | |

| Dimension | 900×3500×1516 mm | |

| Voltage | 380/50 V/Hz | |

| Input power | 62 KW | |

| Inner drum diameter | 600 mm | |

| Inner drum length | 3000 mm | |

| Drive motor | Power | 0.75 W |

| Speed | 1400 rpm | |

| Voltage | 380 V | |

| Exhaust motor | Power | 370 W |

| Speed | 1400 rpm | |

| Voltage | 220 V | |

| Drum speed | 5-37 rpm | |

| Heating type | Electric heating wire | |

| Efficiency | 75 kg/h | |

| DL-6CSTL-D60 electric heating continuous tea steamer machine photos: |

|

|

|

|

|

|

Highly customized tea processing machine to meet your special needs, strictly product quality control is our requirement .

online service

online service +86-595-23142888

+86-595-23142888 chois@delijx.com

chois@delijx.com Chois Dong

Chois Dong 008618120033767

008618120033767 008618959335376

008618959335376