6CRT-55 green tea leaves rolling machine barrel diameter is 550mm, height 400mm, productivity is 75kg/h

TQJ-20 Fresh tea leaf wither rack has bamboo and stainless steel plate, can use for all kinds tea.

DL-6CSTL-Q80 gas heating continuous tea leaf steaming machine can use for many kinds of tea, such as green tea, oolong tea and others.

DL-6CHZ-Q14 tea drying machine can use liquid gas, natural gas and electric, can dry all most kinds tea, such as green tea, black tea, oolong tea and so on.

DL-6CFJ-80 black tea fermentation machine mainly used for processing black tea, let black tea ferment better.

DL-4C-T50A5 handheld one-man tea leaf plucking machine cutting width is 450mm, 500mm, 600mm, use HUASHENG 1E34F gasoline engine.

DL-4CD-35 electric battery operated tea leaf plucker harvesting machine cutting width is 350mm, using backpack lithium battery or lead acid battery.

DL-6CY3-15 tea cake and tea brick molding machine use hydraulic, can press puer tea cake and other tea cake and tea brick.

DL-6CST-50 gas heating green/oolong tea panning machine can use 220V and 380V, inner diameter 50cm, highest temperature can be 350℃, it can process 25kg tea per hour.

DL-6CRH-120B tea leaf bamboo soft basket with cloth covering mainly used for temporary storage of tea, easy to transfer tea between each processing process.

DL-6CFX-435QB used for sorting different kind tea, screen out strip tea, broken tea and tea powder of different specifications

Item NO.:

DL-6CST-50Brand:

DELI ASSISTANTBarrel diameter:

500 mmBarrel length:

850 mmRotating speed:

5-37 rpmFuel type:

GasMaximum temperature:

350 ℃Temperature control:

Automatic controlVoltage:

220V / 380VDimension:

780×1400×1530 mmEfficiency:

25 kg/h

| Description: |

1. Excellent heat insulation, heat preservation and energy saving;

2. Using calcium silicate board, increasing the heat preservation effect and meeting the food hygiene requirements;

3. Increased insulation of the front plate of the drum;

4. Intelligent temperature control system, easy to operate and precise control;

5. Hand and self-integration control, double guarantee;

6. Large feed inlet, easy to feed, and faster discharge. The dryness of the products coming out before and after is more uniform, the taper size is longer, and the material is not dropped;

7. The inner cylinder adopts a steel plate with a thickness of 2.5mm to prevent the deformation of the cylinder at high temperature. The work can store energy, less heat loss, smaller temperature change and more energy saving;

8. Use a controlled water vapor discharge system to save energy.

Application:

This small tea panning machine DL-6CST-50 use gas as fuel, can use liquid gas and natural gas, this tea panning machine suitable for small tea factory and home use, suitable for processing high-quality fine tea.

It can also be used in tourist areas, for tourists DIY processing tea, low energy consumption and high safety, it's the good choice for you !

The machine is small and flexible, suitable for small and medium-sized tea processing plants (fine tea processing and production), using a rotating drum cylinder, tea leaves are more evenly fired, tea leaves are heated without dead ends, with pure handwork Unmatched uniformity and breathability, it is an ideal machine for the production and processing of fine tea. It is an alternative equipment for manual firewood wok.

| Parameter: |

DL-6CST-50 tea leaf fixation machine specification:

| Model | DL-6CST-50 | |

| Dimensions | 780×1400×1530 mm | |

| Voltage | 380/220 V/Hz | |

| Inner barrel diameter | 500 mm | |

| Inner barrel length | 850 mm | |

| Drive motor | Power | 0.75 KW |

| Speed | 1400 rpm | |

| Voltage | 220 V | |

| Exhaust fan | Power | 85 W |

| Speed | 2200 rpm | |

| Voltage | 220 V | |

| Barrel speed | 5-37 rpm | |

| Heating type | Gas | |

| Efficiency | 25 kg/h | |

The above data is based on fresh tea leaf water content of 75-80%.

| Details: |

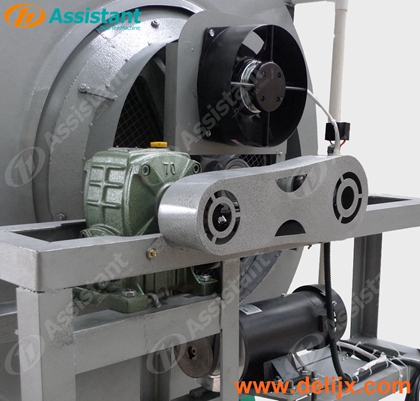

DL-6CST-50 tea leaf panning machine decomposition diagram:

|

① |

Electric control panel |

⑦ |

Heat dissipating switch |

|

② |

Thermometer |

⑧ |

Handle |

|

|

③ |

Outer barrel |

⑨ |

Balance bolt |

|

|

④ |

Inner barrel |

⑩ |

Shock absorber rod |

|

|

⑤ |

nylon wheel |

⑪ |

Combustion zone |

|

|

⑥ |

Ignition switch |

⑫ |

Support frame |

| Advantage: |

|

Integrated multifunctional electric control box The first intelligent temperature control system in tea machinery industry |

|

|

|

| Copper core driving motor |

Gas-fired igniter |

Shock absorber cylinder |

|

|

|

"T" type gas burner |

Calcium silicate board insulation layer |

| DL-6CST-50 green/oolong tea panning equipment photos: |

|

|

|

|

|

Highly customized tea processing machine to meet your special needs, strictly product quality control is our requirement .

online service

online service +86-595-23142888

+86-595-23142888 chois@delijx.com

chois@delijx.com Chois Dong

Chois Dong 008618120033767

008618120033767 008618959335376

008618959335376